Plastics are utilised in nearly all industries, but plastic pollution is an escalating issue. Conventional plastics accumulate in landfills and oceans, and have been growing consistently over the years.

In response, interest is growing around more eco-friendly biopolymers and bioplastics.

The main difference between biopolymers and bioplastics is that biopolymers are a broader class of materials that includes all polymers that are derived from biological sources, while bioplastics are a subset of biopolymers that are specifically designed to be used as plastics.

In other words, all bioplastics are biopolymers, but not all biopolymers are bioplastics.

The quest for creating and using renewable resources to create apt substitutes for plastics is hence understandable. The invention of biopolymers has brought about new hopes in the sector.

The concerns about global warming and plastic waste management have given rise to a strong viewpoint on limiting the use of available carbon sources.

The article here discusses biopolymers, their characterization techniques, frequently used varieties and their applications in various sectors.

Key questions around biopolymers:

- What are biopolymers used for? Biopolymers are used to make plastic alternatives and biodegradable materials.

- Is a biopolymer a plastic? Yes, biopolymers are a form of eco-friendly and biodegradable plastic.

- What products are made from biopolymers? Packaging, medical implants, textiles, electronics, automotive parts, etc.

About biopolymers

Biopolymers are polymers of biological molecules made out of chains of monomeric units bonded together. As the name suggests, these are completely biodegradable and are produced by living organisms.

The base materials for the production of biopolymers are derived from biological sources like plants and plant sources (vegetable oils, sugars, fats, etc), microorganisms, etc.

They provide an alternative to conventional plastics derived from fossil fuels. Some common biopolymers examples include:

- PLA – Polylactic acid from corn starch or sugarcane

- PHA – Polyhydroxyalkanoates from bacteria

- Bio-PE – Bio-based polyethylene from bioethanol

Biopolymers are complex in their structures, especially when compared to synthetic polymers.

Each biopolymer has different properties and applications. This is because they possess complex 3D geometries and patterns which makes them more active in functionality.

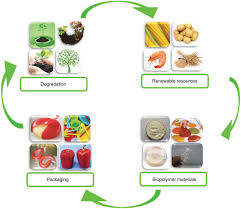

Biodegradable biopolymers break down through natural processes, reducing waste. Compostable biopolymers break down in industrial composting facilities.

Biopolymers are the answer to the modern world’s quest for a substitute for fossil fuel-based polymers.

They are sustainable.

They are biodegradable.

But how viable are these biomaterials?

Today’s headlines often raise questions about using biodegradable or compostable plastics, which are made from renewable materials like vegetable oil, corn starch, wood chips, and food scraps, instead of non-renewable sources such as petroleum.

Replacing synthetic polymers with biopolymers in many of the everyday items we take for granted, could have huge ecological advantages.

The very nature of biopolymers means they can always be renewed—they’re composed of living materials, after all—so we’ll never be at risk of running out of them.

Additionally, biopolymers are biodegradable, produce fewer greenhouse gases during production, and have the potential to reduce our global carbon footprint.

Easy and natural degradation when exposed to the bacteria in soil or even marine sediments makes them a highly valued material in the polymer industry.

Their degradation results in significantly fewer quantities of CO2 emissions which gives them favourable points on Green House Gas reduction.

With growing concerns on global warming, biopolymers are hence a very valuable alternative for future use in various industries.

Interestingly, the production of polymers using biological/renewable sources has been one of the fastest-growing sectors in the last few years.

Classes of biopolymers

Different classification methods are adopted for bipolymers. On the basis of degradability, they can be either biodegradable or non-biodegradable.

On the basis of their source material, they can either be bio-based or non-biobased.

Similarly, on the basis of their polymer type, they can be classified as polyesters, polycarbonates, polyamides, polysaccharides, and vinyl polymers.

Certain classifications are based on the applications of biopolymers. These constitute bio-plastics, bio-surfactants, bio-adhesive, bio-flocculant, bio-detergents, etc.

Characterization techniques used

Biopolymers are characterized in the same way as polymers. Characterization is done to develop the parameters for processing and determine the functional performance of the biopolymers.

Characterization looks into properties like molecular mass, degree of association, conformation, etc.

Various scientific characterization techniques are used for the purpose. These include:

- Fourier Transform Infrared Spectroscopy (FTIR): The technique is used for studying interactions like hydrogen bonding that happens in biopolymers.

- X-Ray diffraction analysis: These techniques are usually utilized to study the crystallinity in biopolymers

- NMR spectroscopy: These techniques help in the assessment of the water-absorbing capability of the biopolymer surfaces.

- Thermal analysis: This technique is used to study the thermal and chemical stability of a biopolymer.

- Scanning Kelvin Probe Microscopy: This technique is used to map the electrostatic potential and electrical properties of the biopolymers.

- VIS-NIR Spectroscopy: This technique is a valuable tool for analyzing the biological sample attributes of biopolymers like polysaccharides and proteins. It is used to check the composition of the material.

Sources of Biopolymers

Biopolymers can be based out of starch, sugar, cellulose or even synthetic materials.

Starch is a naturally occurring polymer within the plant tissues. It is usually obtained from potatoes, maize, wheat, and similar sources. Starch can be melted and deformed thermoplastically to produce a material that has properties similar to conventional plastics. These are known as bioplastics.

Sugar-based biopolymers like Polyhydrobutyrate are started using sucrose which undergoes bacterial fermentation. A small variation in the nutrient composition of bacteria results in biopolymers with different properties. (Such variations are used to alter the properties and create a product of desirable features).

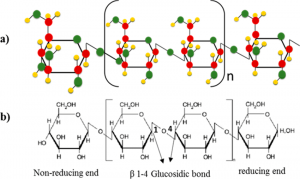

Cellulose derived from plants is another common source for the production of biopolymers. It’s use as cellophane, a popular packaging material is well recognized.

Biopolymers, like their conventional counterparts, are produced in bulk and are then applied for various end uses. Microorganisms have a crucial role in the production of a large variety of biopolymers. These include polysaccharides, polyesters, and polyamides.

Again, it is possible to tailor the end properties of biopolymers by creating small manipulations in the microorganisms and their environment. Microorganisms require specific nutrients and controlled conditions to start the process of fermentation or chemical polymerization of monomers.

Interestingly, biopolymers are considered to be a result of the storage or defensive mechanisms adopted by these microorganisms against environmental conditions.

Algae are a largely used microorganism for the production of bioplastics.

Commonly used biopolymers

Following are the most frequently studied and used biopolymers:

1. Gelatin:

It is a protein made by partial hydrolysis of animal tissues like skin, bones, etc. Gelatin finds various applications in multiple sectors. It is used as an ingredient in drugs for arthritis, brittle bones, weight loss, hair care, etc. Additionally, it is also used in the preparation of certain food products and cosmetics.

2. Starch:

Starch is a carbohydrate which is essentially a polymer made out of amylose and amylopectin. Starch is a polymer of glucose. It is used in the production of paper, textiles, and also as a synthetic additive in detergents, medicines, cosmetics, etc.

3. Cellulose:

Cellulose is the most abundant naturally occurring biopolymer found on the Earth. Just like starch, it is made out of monomer units of glucose. Cotton is a form of cellulose and is highly used in the textile industry.

Modern technologies allow the alteration of various thermal, chemical, mechanical, physical properties of cellulose which makes it suitable for various unique commercial applications.

4. Chitin:

This nitrogen containing polysaccharide is naturally found in the exoskeleton of insects, crustaceans, and arachnids. Chitin is insoluble in almost all organic and inorganic solvents and has oxygen permeation capabilities. This is the reason for its application in the medical industry as wound dressing material.

5. Polylactic Acid (PLA):

PLA is derived from sources like corn starch, sugarcane, roots, etc. PLA can also be produced using lactic acid. PLA has superior weather-resistant properties, high tensile strength, and fracture resistance.

6. Poly(e-Caprolactone) (PCL):

PCL has a low melting point and is hence used as an additive for resins to improve their properties like impact resistance. Its high compatibility with a wide range of other polymers makes it a good additive choice.

Being FDA approved, it is highly used in the medical sector for implants and other purposes.

7. Poly Vinyl Alcohol (PVA):

PVA is a water-soluble synthetic polymer used for applications like thickeners in glue, water-soluble films, coatings, paper markings, etc.

8. Collagen:

This highly abundant natural protein is found in the human muscular-skeleton system. It provides structure and strength to the bones and muscles in the human body. Collagen for commercial applications is derived from bovine, ovine and human sources. It is used in medical products like wound dressings, etc.

9. Polyvinyl Acetate (PVAc):

This thermoplastic is produced by polymerizing vinyl acetate. It is widely used in various fields like medical applications, production of metal nanoparticles, etc.

Uses of Biopolymers

Biopolymers are used to make plastic alternatives and biodegradable materials. As mentioned in the earlier sections, biopolymers are highly compatible with various other materials and are completely biodegradable in nature.

This makes them an excellent choice for improving the performance of other products and materials for various commercial applications.

What are biopolymers used for?

For example, packaging, medical implants, textiles, electronics, and automotive parts, etc. The following are some key application areas for biopolymers:

1. Biomedical applications: Biopolymers are largely being used for medical purposes like tissue engineering, medical devices, implants, wound dressings, pharmaceutical carriers, etc.

Various new studies are being conducted to improve the properties of biomaterials to make them more functionally appropriate for use in the medical industry.

2. Food and packaging sector: Biopolymers are now being used for purposes like food coatings, Edible films, food encapsulation, and food packaging materials, etc. They are not just better in terms of properties like enhancing food shelf life but are also a great substitute for conventional plastic packagings which produce a high carbon footprint.

Biopolymers like starch and PLA are particularly used in the food packaging industry owing to properties like moisture resistance and transparency.

Biopolymer-based compostable packaging materials are increasingly capturing global attention owing to their biodegradable nature, renewability, and compatibility with living organisms.

Various biopolymers used in food packaging include PHA, Starch, and PLA. Good barrier properties of these biopolymers make them a good choice for food packaging. Modern techniques like the addition of nanofiller to biopolymers help in improving their barrier properties.

Bioplastics like PGA (Polyglycolic acid) have great barrier properties and are hence commercially used for various food packaging applications.

3. Nanomaterial synthesis: Metal nanoparticles are commonly used in various industrial applications. However, due to their potential threat to the environment along with biological risks, the interest has shifted towards developing more sustainable processes.

Biopolymers are now being considered as suitable caping and reducing agents for the production of nanomaterials. Various biopolymers like cellulose, gelatin, PVA, Chitosan, PVP, etc are used for the synthesis of nanoparticles.

4. Water filtration: The use of nanotechnology for the provision of safe drinking water is the latest development in the sector. Developing nanomaterials that have antibacterial and antifungal properties and can effectively remove toxic metals like lead, arsenic, etc from potable water is one of the latest applications of biopolymers.

Biopolymers like Chitosan are used as flocculants in water treatment processes.

The future of biopolymers

Biodegradable plastics production is steadily growing, with an estimated 2.6 million tons forecast to be produced by 2023 (65% of which is to be used for packaging).

It is also anticipated that by 2023, polyethylene furanoate will be introduced to the market, which could become the new novelty in biobased plastic for beverage bottles.

Final thoughts:

With increasing awareness of environmental issues and sustainable development, new developments in the field of biodegradable polymers are being carried out.

The need to replace fossil fuel-based polymers and reduce the overall carbon footprint has been emphasied by environmentalists around the globe. Biopolymers with their great compatibility properties as well as biodegradability features make them one of the most promising materials for use in various industrial and commercial applications in the times to come.