The planet seems to be drowning in a sea of plastics. The accumulation of plastic wastes is one of the biggest environmental concerns of the century. From landfills to the oceans, piles of plastic bags and other plastics dumps are the most common sight.

The development of bioplastics and biodegradable plastics from renewable resources has been considered significant for addressing the issue of waste management. While high cost has been a barrier in the growth curve for these organic plastics, the market is still growing.

Why?

Following have been considered as the key factors contributing to the development of bioplastic industry:

- Government policies towards eco-friendly materials and sustainable development

- Environmental concerns like pollution, climate change, etc

- Consumer education and preference for green products

- Multiple applications and suitability for the commercial sector

- Acknowledgment by the plastic industry

- The rising costs of fossil fuels

Let us begin by understanding more about bioplastics and their key commercial uses.

What are bioplastics?

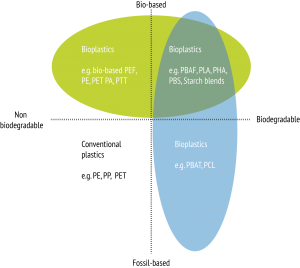

Bioplastics, as the name suggests are those that are derived from biological materials or biodegradable sources like corn starch, food waste or even agricultural bi-products. Unlike their plastic counterparts which are derived out of fossil fuels and petrochemical polymers, biobased plastics are easy to decompose in a natural environment. This means reduced negative environmental impacts as well as sustainable development for the planet.

Bioplastics vs Biodegradable Plastics

So, are bioplastics, biodegradable, and compostable plastics simply two synonymous words?

No.

While bioplastics are the ones made out of organic materials, biodegradable plastics are petroleum-based but combined with additives which makes them easier to decompose. While both sound equally green, significant environmental concerns have been raised over the decay process of biodegradable plastics.

Biodegradable plastics, despite the presence of additives, need suitable temperature, light, moisture, and oxygen conditions to decompose. In the absence of these, biodegradable plastics can accumulate just like traditional plastics. It is for this reason that biodegradable plastics are not home compostable and need to be sent to industrial composting units. These composting facilities provide the required set of conditions for biodegradation of plastics.

However, bioplastics, being completely organic in nature are easy to break down at the end of useful life cycle. It gives bioplastics an edge over the biodegradable varieties when it comes to addressing the ecological issues.

Types of Bioplastics

Following are the key types of biobased plastics that are used within various commercial industries:

- Starch-based bioplastics- These are the most widely utilized varieties. Their blends with biodegradable polyester can produce highly effective versions like polylactic acid (PLA) or polycaprolactone. These blends are significantly water-resistant. Starch-based films are used for producing composting bags. Polylactic acid or PLAs are used in the manufacturing process of food packaging materials like films, cups, containers, bioplastic bottles, etc.

- Protein-based bioplastics- Biobased plastics made out of raw materials like proteins like wheat gluten and soy protein are used in the automobile industry as well as for production of various electronic parts.

- Cellulose-based bioplastics- Cellulose when added to starch improves its properties like strength, water resistance, etc. This makes them great for high-quality packaging material.

- Aliphatic polyesters- Commonly used bio versions of aliphatic polyester include polyhydroxyalkanoates (PHA), polyhydroxyhexanoate(PHH), poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV).

- Lipid-based bioplastics- Fats and oils derived from plant and animal sources are used to prepare certain bioplastic classes.

How are Bioplastics made?

The bioplastic production process is a simple task that can easily be taken up as a DIY activity at home. With simple raw materials like starches, gelatins, agar, vinegar, etc, a sheet or a mold of bioplastics can be prepared.

Following is one simple technique to prepare bioplastics using agar powder. Mix up 3g of glycerol, 12g of gelatin/agar, 60ml of hot water and stir the ingredients together. Heat up the mixtures on medium heat on a stove. Add food colors if you want.

Keep up the heating till the mixture begins to froth and the thermometer shows a reading of 95-degree celsius. Remove the pan from heat and skim out the froth. Pour the mixture on to a smooth surface covered with a foil or even a mold of your choice.

Let the plastic cool and harden for a couple of days.

Voila! Your homemade bioplastic is ready!

The Top 5 Commercial Uses of Bioplastics

Various end uses of bioplastics have been accepted within the commercial sectors. While packaging and bags take up a significant share of the bioplastic market, their usage in other industries has been growing too.

Following is our list of top 5 commercial applications of biodegradable plastics.

1. Packaging and Bags

Various plastic packaging products are being manufactured using bioplastic sources. Some of these include bioplastic packaging, bioplastic bags, bottles, biodegradable compost bags, disposable cutlery, and tableware, etc.

The bioplastic materials used in the food packaging industry are good at maintaining quality. The food contained within remains free of toxic chemicals while being able to maintain its freshness. Additionally, mechanical properties can be controlled and changed as per the industry requirements.

Biodegradable shopping bags are another important application of these organic plastics. The additives used in the plastics make them easy to biodegrade when exposed to air, light, or water.

Biodegradable bags can be made from starches (along with polyethylene and heavy metals) or starches combined with biodegradable polymers like Polylactic Acid, PLA.

Another variety that’s gaining popularity is the oxo-biodegradable plastic bags which use certain additive classes that breakdown the polymers at a faster speed.

Various product developers are now manufacturing biodegradable or bioplastic based bags for use in waste collection, compositing as well as shopping purposes.

Being completely organic in nature, the polymers of these compostable plastics break down to eventually release carbon dioxide, water and organic matter in the environment. The environmental impacts are hence negligible as compared to conventional plastics.

2. Houseware and Kitchenware

Biodegradable plastics made from renewable resources have been slowly replacing the markets for conventional plastics for disposable houseware and kitchen utilities. Things like storage utensils, biodegradable cups, bio plastic bottles, hangers, plastic shelves, toys, bathroom utilities, etc.

Additionally, food and hospitality industries have been making a shift towards biodegradable plastic items like biobased cutlery and tableware. Their benefits, especially in comparison to conventional plastics are significant.

3. Medical Equipment

Medical industry takes up a large share of the biodegradable plastic market. Various medical procedures use bioplastics for their excellent properties.

Non-toxic versions of biodegradable plastics (made out of renewable resources) are used for sutures in heart operations and other similar procedures. The sutures are easy to sterilize, give the required tensile strength properties and get dissolved easily within the body.

Other biodegradable medical devices like orthopedic pins, dental implants, skin staplers, dissolvable medical screws, etc are also highly used within the industry.

Biodegradable polymers like PolyActive and OctoDEX have been used for site-specific drug delivery. The linear release and biodegradation properties of these polymers help in the controlled release of proteins for local administration.

The overall applications of biodegradable and bioplastics in medical and pharmaceutical technologies have hence been revolutionary.

4. Electronics

Consumer electronic goods take up a significant share of the plastics market. Plastics are being used to produce circuit boards, casings, tablets, etc.

Bioplastics have now been introduced in the consumer electronics world which is a big contributor to plastic waste.

Electronic items like touch screen computer casings, keyboards, earphones, mobile phones, loudspeakers, laptops, game consoles, mobile casings, mouse, vacuum cleaners, etc are now being made out of bioplastics and biodegradable plastics.

Optimized PLA compounds are largely being utilized within the consumer electronics market. PLA blends provided added properties like impact resistance, water resistance, stability, high gloss finish, etc.

5. Automobile industry

The modern automotive industry has seen various revolutionary changes. In terms of reducing the overall carbon footprint, various steps have been taken. Shifting to fuel-efficient vehicles to converting to greener fuel systems have contributed positively towards environmental conservation efforts.

Plastic products have been an important part of the automotive sector. However, the concerns over the recyclability and the growing plastic wastes emerging from this sector have been real.

This is perhaps the reason for the automobile industry to shift towards bioplastics. Various leading automobile brands are now using bioplastics like bio polyester and bio polyamides. Besides being significantly beneficial to the environment, these bioplastics exhibit great performance.

The excellent qualities, as well as the biodegradable nature of these materials, have made manufacturers take notice. Automobile components like the dashboard, interior and exterior features, headliners, sun visors, floor mats, seat cushion covers, etc.

Leading manufacturers like Toyota have been forerunners in using bioplastics for various automotive components.

Various reports suggest that the global bioplastic markets will earn around $96,627 million by the end of the year 2025. Challenging the dominance of plastics in various commercial applications, bioplastics are now being preferred by multiple industries.

The bioplastics market is young and developing but with enormous potential. While it is true that bioplastics currently represent only about one percent of the total plastics produced globally, the market has been showing steady growth. The number of interested manufacturers and end-users has been increasing every year.

Additionally, increasing consumer awareness and demand for sustainable products has created a surge in the bioplastic demand graphs. With the growing understanding of ecology-related issues like pollution, climate change, etc. consumers are showing increased acceptance of sustainable products like bioplastics.