Plastic packaging has been a major source of plastic pollution over the past century. This packaging will end up in landfills or the ocean when poorly disposed of.

Plastic takes centuries to break down, and even then, it will persist as microplastics, which are harmful to people and animals.

In light of this problem, many plant-based, biodegradable alternatives have been created to replace plastic packaging. Among these alternatives is cellulose packaging.

What is cellulose?

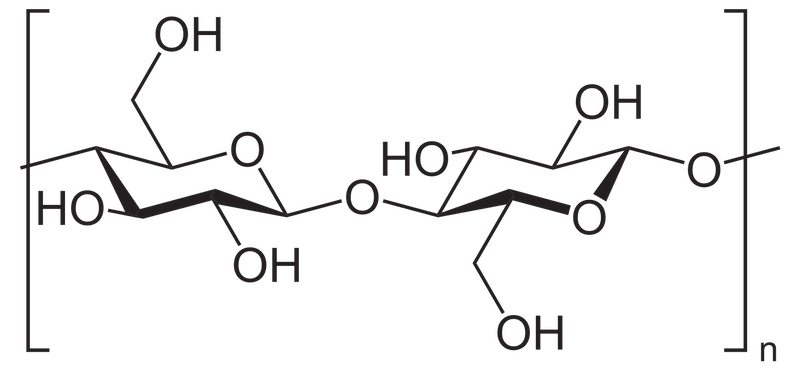

Cellulose is an organic carbohydrate polymer that makes up the cell walls of plants and algae. This makes it the most abundant biopolymer on Earth.

Although animals do not produce cellulose, the polymer is vital to their survival. For instance, many insects use it as food or building material.

Cellulose is also used to manufacture environmentally friendly alternatives to plastic or styrofoam products due to its abundance and stiffness.

Most importantly, cellulose is a renewable resource, unlike petroleum.

Wood pulp, derived from trees, is the most common source of cellulose. But it can also be sourced from agricultural waste. And our farms are already producing all the cellulose we need for our manufacturing needs.

Thus, when the Earth’s fossil fuel deposits are inevitably depleted, nature and agriculture will provide better alternatives.

Read also: Biopolymers: A Complete Guide for 2023

What is cellulose packaging?

Cellulose packaging is made from cellulose-based materials such as paper, cardboard, or cellophane.

Cellulose can also be used to produce a type of bioplastic that is biodegradable and more environmentally friendly than petroleum-based plastics. These bioplastics can be utilized to make food containers, bottles, cups or trays.

Can cellulose replace plastic?

With an annual growth rate of 5–10% over the past decade, cellulose is already at the forefront of replacing plastic in everyday use.

Cellophane, especially, is set to replace plastic film packaging soon. According to a Future Market Insights report, cellulose packaging will have a compound annual growth rate of 4.9% between 2018 and 2028.

The same report predicted that 70% of that growth will occur in the food and beverage sector. Biodegradable cellophane packaging film and bags, in particular, have the highest expected growth category.

How is cellulose packaging made?

The production of cellulose packaging usually follows these steps:

- Sourcing and harvesting cellulose-rich materials like wood, algae, cotton, or agricultural waste.

- Breaking down the cellulose into pulp through mechanical or chemical processes.

- Further refining the pulp by removing impurities.

- Forming the cellulose into sheets or other desired packaging shapes through extrusion or molding.

- Adding any necessary coatings or adhesives to enhance the functionality of the packaging.

Types of cellulose packaging

Cellulose can be used to make a wide variety of materials for making packaging with:

- Cellophane is a transparent, thin, biodegradable plastic-like material originally used as a candy wrapping but has since expanded into an alternative food packaging.

- Paper and cardboard are both considered cellulose-based due to being made from wood pulp.

- Bioplastics can use cellulose as a base material. These are made using cellulose esters and derivatives made from cellulose. Cellulose is also added to starch to create biopolymers that have enhanced mechanical properties and are highly water-resistant, too.

Read also: 5 Important Types of Bioplastics and Their Recipes

Uses of cellulose packaging

Cellulose packaging has been used in a wide variety of applications throughout the packaging industry:

- Food packaging: Paper, cardboard, or cellophane is used to store and package foodstuffs. Cellulose is considered one of the most popular food packaging options.

- Film packaging: Cellophane film has become popular as an alternative to plastic film packaging. It can be used for food, soap, and even gift items.

source:

Xiamen Changsu Industrial Co., Ltd. - Cannabis packaging: Many companies that produce recreational marijuana also use hemp byproducts as material for their packaging.

- Pharmaceutical packaging: Cellulose derivatives, such as bioadhesive polymers made of cellulose ether, are becoming the choice of material in medicine and healthcare packaging.

- Corrugated packaging: This low-cost and eco-friendly packaging is used in almost every industry, from storage to transportation.

- Electronic packaging: Various industries use printed electronics, but their plastic components add to the e-waste problem. Cellulose fibrils can be used instead. These will improve sustainability and recyclability without sacrificing the desired mechanical properties.

- Female hygiene products: Germany-based Kelheim Fibres has developed plant-based fiber solutions for absorbent hygiene products. These enable the replacement of synthetic fibers without sacrificing performance.

- Cosmetic packaging: The cosmetic and personal care industry has been moving towards more sustainable packaging options. Cellulose film packaging can be used for naturally-derived solid cosmetic products.

- E-commerce and delivery: The rapid growth of online shopping has led to the need for lightweight and sustainable packaging solutions. Cellulose film packaging can fill these needs with its excellent barrier properties, gas and moisture resistance, and lightweightness.

Read also: Bioplastics- Top 5 Commercial Uses

Cellophane film bags for food packaging

Cellophane film bags offer an eco-friendly alternative to plastic bags in food packaging. Among its environmental benefits:

- Sustainable: Because cellophane is created from cellulose harvested from plants, it is a sustainable product sourced from bio-based, renewable resources.

- Biodegradable: Cellophane film can decompose in the environment without leaving harmful waste behind.

- Compostable: Cellophane is a compostable plastic that can be safely placed in your compost pile at home or in a public compost bin without requiring specialized facilities or processes.

Read: Biodegradable vs compostable products.

In addition to its eco-friendliness, cellophane film is also good for food packaging because of the following benefits:

- Low-cost: Cellophane is cheaper than other eco-friendly plastic alternatives due to the abundance of its source material.

- Moisture-resistant: Biodegradable cellophane bags resist moisture and water vapor, making them an excellent choice for displaying and storing food items.

- Oil-resistant: Cellophane film naturally resists oils and fats, making them great for containing baked goods, nuts, and other greasy foods.

- Heat sealable: Cellophane is heat sealable. With an electrical pulse sealer, you can quickly and easily heat seal and protect food products stored in cellophane bags.

- Aroma retention: Cellophane film can retain a food’s aroma without affecting it.

Advantages and disadvantages of cellulose packaging

Cellulose is used in various practical applications because of its many advantages over plastic. But it also has its disadvantages.

Advantages of cellulose

Cellulose packaging offers many advantages that make it attractive as a material for replacing plastic:

- Renewability: Cellulose is derived from renewable resources such as cotton and algae, which helps to reduce the reliance on finite fossil fuels.

- Biodegradability: Unlike traditional plastic packaging, cellulose packaging is biodegradable, lowering the amount of waste in the environment.

- Compostability: Cellulose packaging can be composted, bolstering soil nutrition and promoting plant growth.

- Lightweight: Cellulose is lighter than traditional materials, reducing the carbon emissions from transportation and distribution.

- Strong: Despite being lightweight, cellulose is strong and durable, providing adequate protection.

- Temperature resistance: Cellulose packaging is resistant to changes in temperature, making it suitable for transporting pre-prepared food products.

- Versatility: Cellulose can be molded and customized to fit any role.

- Low-cost: Cellulose packaging has been around since 1912 as a byproduct of the paper industry. This, combined with the abundance of its source materials, gives it a lower cost than other eco-friendly plastic alternatives.

- Lower carbon footprint: The production of cellulose packaging uses less energy while emitting fewer greenhouse gases during manufacturing. Additionally, it reduces dependence on fossil fuels and, thus, greenhouse gas emissions.

- Transparency: Cellophane and cellulose-based bioplastics are easier to make clear and transparent compared to conventional plastics.

- Non-toxic: Cellulose is inert and will not leach toxins into your food or the environment.

Disadvantages of cellulose

However, there are some disadvantages and limitations when it comes to using cellulose packaging:

- Not waterproof: Although they can be made moisture-resistant, cellulose-based materials are not waterproof. In fact, it can take merely ten days for an uncoated cellophane film to degrade in water.

- Durability: While strong, cellulose is less durable than conventional plastics.

- Water-intensive production: Cellulose-related industries require significant volumes of water. It can take 10 liters of water to produce a single sheet of A4 paper.

- Not suitable for food preservation: Unlike other materials, they do not extend shelf life alone. If they do, it is only in conjunction with different materials that provide a barrier against external agents.

- Not cold resistant: While resistant to high temperatures, cellulose film packaging is generally not suitable for cold storage. Thus, they are not recommended for freezer storage.

- Specialized recycling: While cellulose film packaging is biodegradable and compostable, it requires specialized facilities to ensure effective recycling.

Cellulose packaging disposal

In theory, the biodegradability of cellulose packaging means that you can throw them away and let them decompose by themselves. However, it is always better to dispose of your biodegradable waste properly.

Here are some tips for proper disposal of your cellulose packaging:

- Compost heap: If you have a compost heap or bin at home, you can put your cellulose packaging waste into it. Be sure to crumple it up instead of lying it flat in your pile, as this creates air pockets necessary for the decomposition process.

- Public or community compost bin: If your community has a shared or public composting bin, you can put your cellulose packaging into it. But first, you should check with your local council to ensure this waste is going for industrial composting.

- Food waste bin: This would also be suitable, but it might be best to check what the council does with this waste.

- General waste bin: Although not ideal, there are no adverse effects – it will remain inert and not biodegrade due to low moisture content.

How is cellulose recycled?

Certain cellulose-based packaging can be recycled. Paper and cardboard, for example, can be recycled to ensure a circular economy.

The recycling process for paper and cardboard goes as follows:

- Collection: The paper and cardboard waste is collected in dedicated recycling bins. It should not be thrown in with general trash, or it will not be recycled.

- Sorting: Once the waste is collected, it needs to be sorted according to the type and quality of the paper and cardboard. For example, corrugated cardboard should be separated from paperboard, and clean paper should be separated from contaminated paper.

- Baling: After sorting, the paper and cardboard are compacted into bales using a baler machine. This process helps reduce the waste volume and makes it easier to transport and store.

- Transportation: The baled paper and cardboard are then transported to a recycling facility and further processed.

- Processing: The paper and cardboard bales are opened at the recycling facility, and the materials are shredded into small pieces. The shredded paper and cardboard are mixed with water to create a pulp, which is used to make new paper and cardboard products.

Bioplastics can also be recycled. In fact, recycling bioplastics is considered preferable over composting due to its lengthy decomposition time.

There are two different methods of recycling bioplastics:

- Mechanical recycling: Specialized facilities for collecting and recycling bioplastic waste are available. At these facilities, separated bioplastics are re-processed through remelting or granulation to be reused for new products.

- Chemical recycling: Also known as feedstock recovery or tertiary recycling, this process is where plastics are converted into monomers, oligomers, or hydrocarbons that can be used again to produce virgin polymers.

However, not all cellulose packaging can be recycled. Cellophane, for example, is non-recyclable, and thus, it is better to compost cellophane film packaging waste.

Where to buy cellulose packaging?

Cellulose packaging is readily available from popular online shopping websites such as Alibaba.

They can also be bought from most bulk suppliers.

FAQ

Is cellulose a waste product?

Cellulose is an essential component in plants. However, it often ends up as agricultural waste since humans only require a small amount in their diets.

As such, using agricultural waste to produce cellulose packaging can be a suitable method of using a byproduct of our food industry.

What else can be made from cellulose?

Besides packaging, cellulose can be used to make various products. Today, cellulose is used to make clothes, cardboard, coffee filters, and countless other everyday items.

Is cellulose sustainable?

Cellulose, as a whole, is considered more sustainable than petroleum-based plastics. It is biodegradable, sourced from renewable resources, and has a lower carbon footprint.

However, not all cellulose-based products are equal. Some methods of producing cellulose, such as the traditional viscose process, have been criticized for using harmful chemicals and high water consumption.

Is cellulose packaging recyclable?

Cellulose-based bioplastics, paper, and cardboard can be recycled through the normal processes depending on the product.

On the other hand, cellulose film packaging requires specialized facilities to be recycled effectively. Thus, it is usually better to compost it.

Is cellulose packaging biodegradable?

Most cellulose packaging, such as cellophane, biodegrades in the environment, leaving behind no harmful waste.

However, certain cellulose-based bioplastics are not biodegradable and require specialized disposal facilities.

Is cellulose packaging compostable?

Most biodegradable cellulose packaging can be safely composted in your home’s compost heap or bin.

How long does it take for cellulose to decompose?

Tests have shown cellulose packaging biodegrades in 28–60 days if the product is uncoated and 80–120 days if coated. It also degrades in the water in 10 days if it’s uncoated and around a month if it’s coated.

Is cellulose packaging eco-friendly?

Cellulose packaging is more eco-friendly than conventional plastics due to its biodegradability, lower carbon footprint, and renewable sources.

However, its production may also use more water, resulting in more significant water shortages and pollution.

Some cellulose packaging may also be treated with chemicals that harm the environment or people.

Is cellulose better than plastic?

Cellulose is considered a more environmentally friendly alternative to plastic for the following reasons:

- It is biodegradable and compostable.

- It has a lower carbon footprint.

- The production cost is cheaper than plastic.

- Plastic processing consumes as much as 4% of the world’s total oil, contributing to growing scarcity. By contrast, cellulose is the most abundant biopolymer on Earth due to being a vital component of plants and algae.

Is cellulose packaging expensive?

Cellulose packaging is cheaper than other eco-friendly plastic alternatives due to the abundance of its source materials.

However, cellulose packaging remains more costly than plastic. This is due to the cost of raw materials, manufacturing processes, and specialized equipment.

Regardless, cellulose packaging will be more cost-effective than plastic due to using agricultural waste and wood pulp, both of which will remain abundant in the future, unlike oil.

As improvements in cellulose packaging technology are made, they will only become cheaper until they can effectively compete with plastic on the market.

Is cellulose waterproof?

No, cellulose is not waterproof. Although cellulose packaging has a high moisture resistance, it fares poorly when wet. This stems from cellulose fibers’ hydrophilicity (water attraction) and low ductility.

Is cellulose flammable?

Yes, cellulose is flammable. However, most cellulose packaging may be treated to give it a high heat resistance. Despite this, you should not burn any cellulose packaging.

Cellophane, especially, can release potentially dangerous chemicals into the air when burned. And that is on top of creating fire hazards.

The future of cellulose

As the world turns towards sustainability, alternatives to plastic will only grow more popular. And that is no exception with cellulose. Many industries have already adopted widespread cellulose packaging due to rising demand for eco-friendly products.

With growing interest and investment in the development of cellulose packaging technology, improvements will be made, and the range of its applications will be expanded. Future advancements may lead to integrating cellulose with other materials to enhance performance.

Cellulose has emerged as one of the most popular environmentally friendly alternatives to plastic thanks to its abundance, sustainability, and biodegradability. With ongoing developments and increasing global adoption by both consumers and industries, the future of cellulose packaging will be bright.